QUALITY. ASSURANCE.

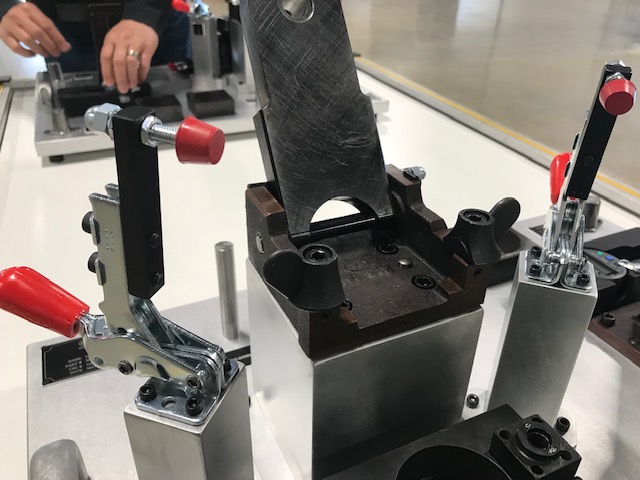

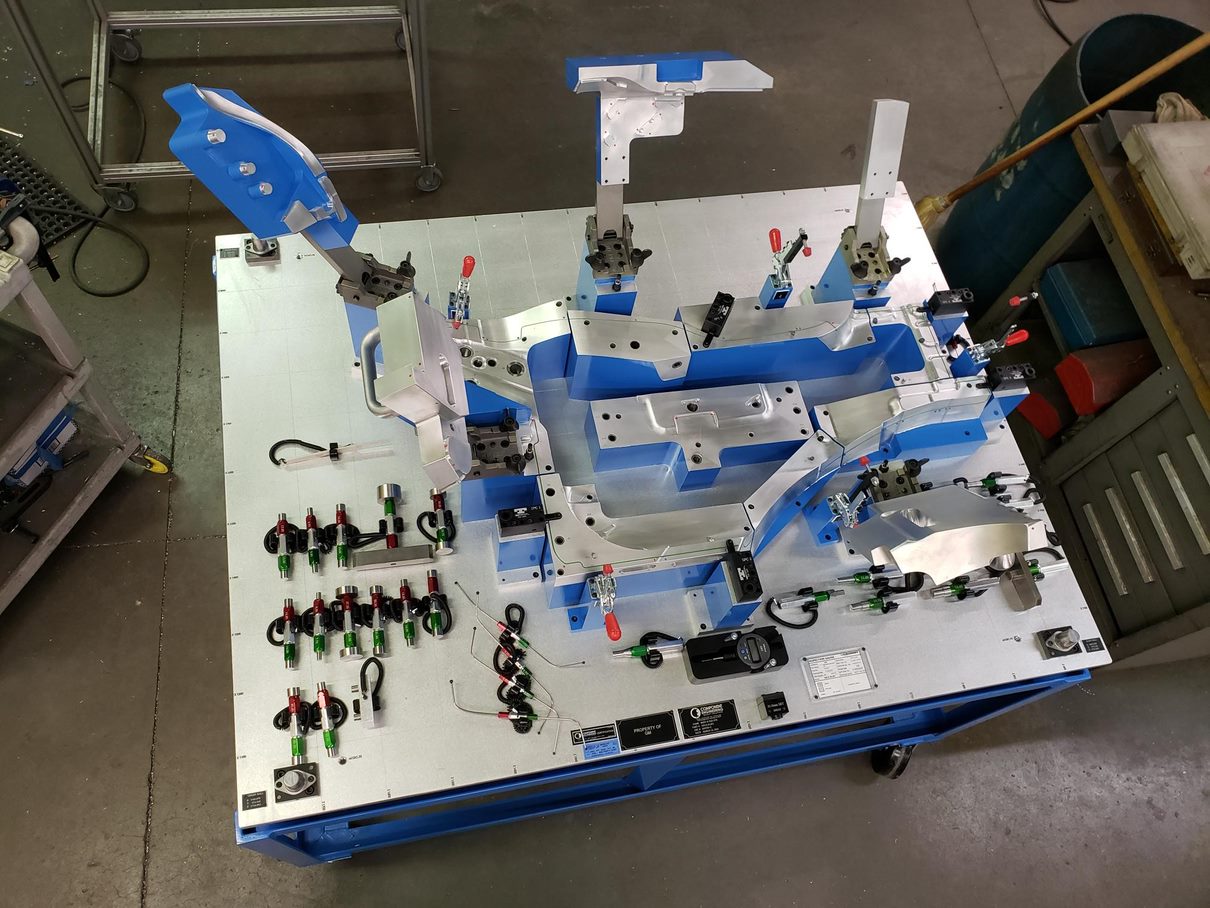

Component Engineering designs and delivers the inspection tools you need to ensure quality finished parts.

We Build Solutions

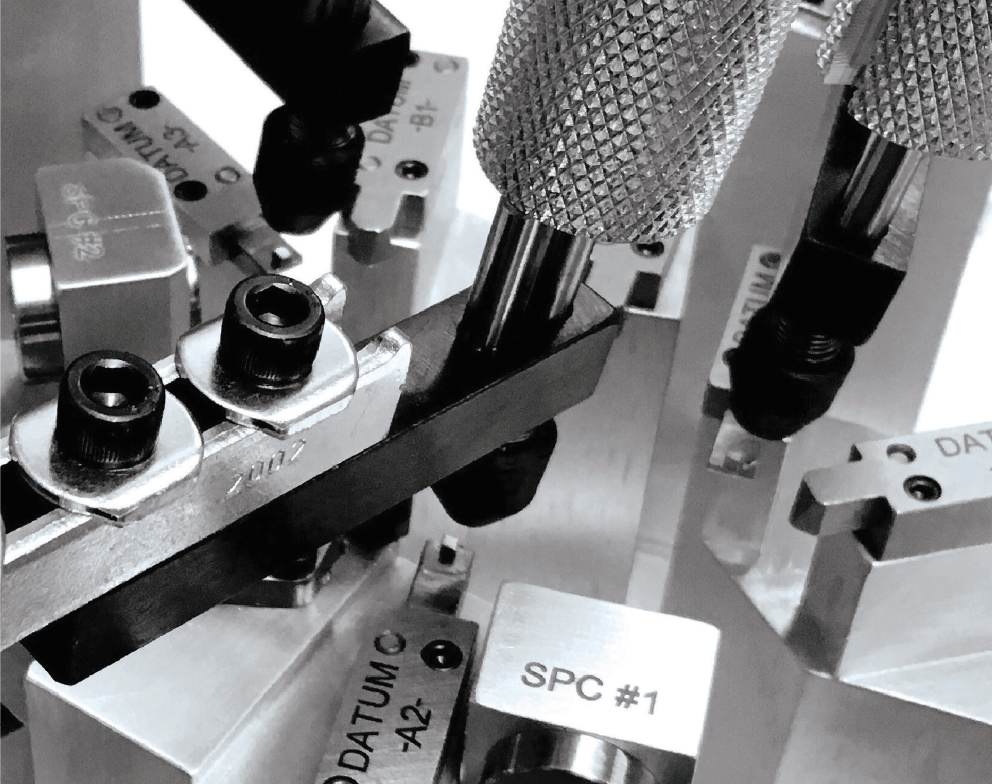

We offer a range of quality inspection options, from simple pass / fail gages and checking fixtures, to more complex automated inspection solutions that capture, analyze, and report variable data results.

Each solution is custom designed and built to ensure finished parts meet customer defined tolerances and specifications.

READ OUR CASE STUDIES

We Deliver

QUALITY ASSURANCE | From basic to complex, our quality inspection solutions ensure you deliver consistent quality parts, assemblies, and finished products.

TAILORED SOLUTIONS | Every process, part, and product are unique. That’s why we partner with you and your team in designing solutions tailored to your process, people, and output requirements.

IMPROVED RESULTS | Good quality inspection does more than check parts – it can help reduce waste and rework, complement your workforce, and improve production throughput – all of which improve your bottom line.

What Sets Us Apart

WE SPECIALIZE IN HUMAN-CENTERED AUTOMATION | We design solutions that create better, safer work environments for your employees by engaging with your team from concept through deployment and replacing repetitive, physically challenging tasks.

WE SELL SOLUTIONS | Anyone can sell you a machine. We’re interested in solving your manufacturing challenges with you. By taking a holistic approach, and viewing processes from beginning to end, together we can arrive at a future-flexible solution that you’ll use in your manufacturing process for years to come.

WE’RE WITH YOU UNTIL WE GET IT RIGHT | We pride ourselves in sticking with our customers beyond installation to ensure everything is working properly, we’ve solved the intended problem, and your team is trained and ready to take over. If it isn’t right, we’ll stay until it is.

CONNECT WITH US, AND LET’S HAVE A CONVERSATION

West Michigan and Beyond

International Customers | Mexico, Costa Rica, Canada

CONNECT WITH US, AND LET’S HAVE A CONVERSATION!

"